Piston Tank Ballast System

One of the more popular ballast systems, especially in Europe, is the Piston Tank Ballast System. This approach was popularized by the German manufacturer Alexander Engel KG. Engel reports on their website that they have sold more than 30,000 piston tanks worldwide.

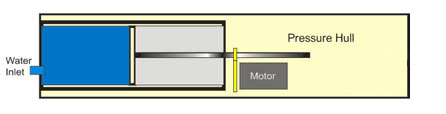

The heart of this ballast system is the piston tank itself. These are self-contained units that are essentially a large plunger moving in an enclosed cylinder which serves as a ballast tank. The plunger is driven by a dedicated motor turning a jackscrew on which it is mounted. When retreating, the plunger draws water into the ballast tank causing the model to submerge. When advancing, the plunger pushes water out of the tank, emptying it and causing the boat to surface.

Micro switches stop the motor at predetermined limits. Additional electronics can afford proportional control of the plunger to maintain near-neutral buoyancy at a given depth. When coupled with a depth keeper (see electronics course), very precise depth control can be maintained -- to the point where the model can hover autonomously.

Piston tanks are normally installed within the watertight compartment of a model submarine. They are commonly used in dry hull submarines which have larger internal dry space. However, there are examples of pistons being used within watertight cylinders. As air is evacuated from the tank it is forced into the dry compartment, increasing the air pressure. Care must be taken during design and construction so that seals, hatches, and endcaps fully withstand changes in pressure.

When a single piston tank is utilized in

a model, the trim of the submarine will be affected

during the fill and empty cycles as the center of

gravity of the model shifts. Typical piston tank

systems use two tanks located fore

and aft. This maintains the correct center of gravity

while filling/emptying ballast. Depending on the

method of control used, the pitch of the boat can

be adjusted by making one tank slightly more or less

full than the other.

Compared to other ballast systems, piston tanks may

take more time to affect ballast changes. For the

electronically challenged they are a bit more involved to build from scratch

due to the switches and motor used to control the plunger positioning. Also,

they require a larger amount of dry space to house the

unit and allow the jackscrew to extend and retract. Piston

tank systems, however, are quite robust, require

little maintenance, and offer amazing levels of control.

Contributor: Bob Martin, Jeff LaRue

Got questions? Join the conversation on our message boards.